ENCAST

Encast: Implementing a new line of defence to avoid the catastrophic collapse of precast buildings

Encast is an ERC Proof of Concept project hosted at the Universitat Politècnica de València.

The overall aim of Encast is to develop versatile and trustworthy design tools for implementing fuse-based segmentation in precast concrete buildings to facilitate its market penetration.

The project started in 2025 and spans a total duration of 1,5 years.

IMPLEMENTING FUSE-BASED SEGMENTATION IN PRECAST BUILDINGS

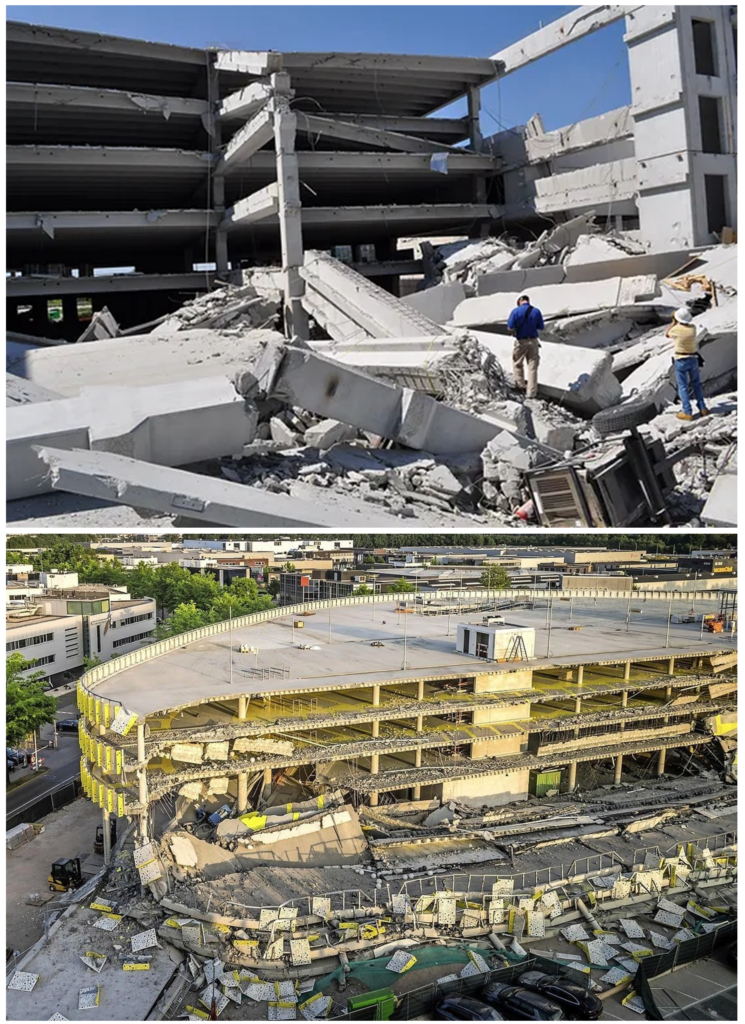

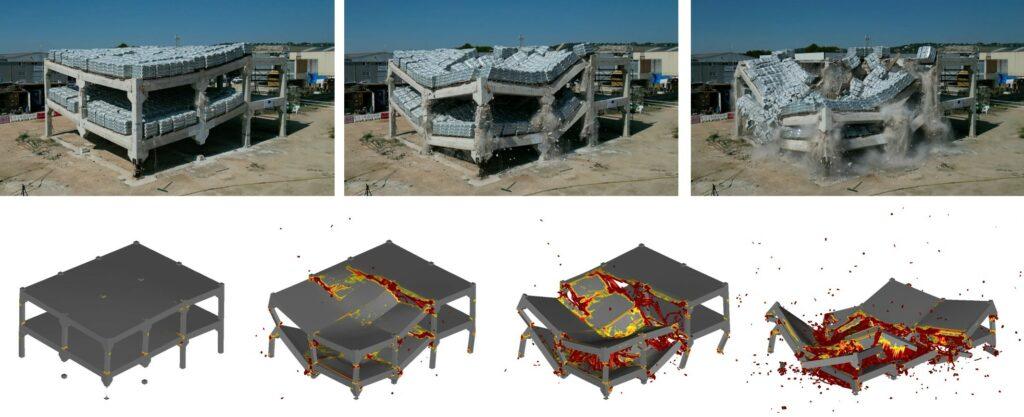

Disastrous building collapses often occur due to the propagation of local-initial failures. Although effective for small initial failures, current design approaches addressing this issue can inadvertently increase the risk of catastrophic collapse propagation after large initial failures. The ERC Consolidator Grant Endure has introduced a novel fuse-based segmentation design approach to overcome this alarming limitation, successfully testing a full-scale precast building to validate its effectiveness. While this approach can be advantageous for different types of structures, its implementation in precast concrete buildings is key to maximizing its impact. Due to several advantages in terms of efficiency and sustainability, precast structures are being increasingly used for high-occupancy and critical buildings. Incorporating fuse-based segmentation in these structural systems would thus provide a new last line of defence against catastrophic failures in the buildings for which the consequences of such an occurrence are most severe. However, at this stage of development, the design of a fuse-based segmented precast building requires advanced computational analysis and several iterative procedures that are unfeasible for most building projects. Such complexity can hinder the adoption of fuse-based segmentation in practice. Therefore, truly unlocking the market penetration potential of fuse-based segmentation solutions for precast buildings requires cost-effective implementation tools and validation across a broader range of precast systems. Encast aims to bridge these gaps by simplifying design procedures, developing user-friendly software, performing experimental demonstrations, and crafting a tailored exploitation strategy for fuse-based segmentation solutions for precast buildings. The project’s success will lead to wider adoption of robust precast systems, helping deliver more affordable and sustainable buildings that contribute to improving societal resilience.

OBJECTIVES

The overall aim of Encast is to develop versatile and trustworthy design tools for implementing fuse-based segmentation in precast concrete buildings to facilitate its market penetration. To achieve this central goal, the project is focused on the following four specific objectives:

- Objective 1: To develop a simplified design procedure for the fuse-based segmentation of precast buildings and produce a practical design guide.

- Objective 2: To develop versatile design software tools to facilitate the implementation of the fuse-based segmentation approach in different well-established precast solutions.

- Objective 3: To demonstrate the effectiveness of the developed tools through laboratory-scale tests of subassemblies of different precast systems.

- Objective 4: To develop a preliminary business model and engage with relevant stakeholders to promote the use of fuse-based segmentation.

METHODOLOGY

Four work packages (WPs) have been defined to achieve the overall aim of Encast.

WP1. Simplified design procedure and practical design guide

In the origin ERC Consolidator Grant Endure, developing fuse-based segmentation designs required high-fidelity collapse simulations that are unfeasible for most building projects. Fuse-based segmentation will not be used by practitioners until such designs can be defined with simpler and more cost-effective methods. Therefore, WP1 of Encast will build on the findings of Endure, performing applied research to develop a general simplified procedure for the fuse-based segmentation design of precast buildings.

To ensure that the simplified design procedure is employed by practitioners, it will be disseminated in the form of a practical guide.

WP2. Versatile design software tools

Although the practical guide produced in WP1 will clarify methodological aspects of the simplified procedure, an efficient and fast way of integrating it in the everyday workflow of building designers is required to ensure its widespread adoption. As such, WP2 is mainly concerned with implementing the simplified design procedure developed in WP1 in the form of software tools in order to accelerate and facilitate its correct usage by building designers.

WP3. Validation of developed tools in representative laboratory-scale demonstrators

In WP3, scaled-down subassemblies of precast systems designed using the tools developed in WP1 and WP2 will be tested under extreme loading conditions to validate and demonstrate the effectiveness of these tools. Two subassemblies of precast systems with connections that differ significantly from those tested in Endure, but that still rely on practical construction methods, will be selected to test and demonstrate the range of applicability of fuse-based segmentation.

WP4. Engagement and exploitation

WP4 has been conceived to maximise the impact of Encast and to prepare the future exploitation of our solutions in the precast concrete sector. Our objective will be to develop a business model (BM) and exploitation plan (EP) and engage with relevant stakeholders to promote the use of fuse-based segmentation.

IMPACT

Encast is expected to have a considerable scientific and technological impact through the experimental validation of fuse-based segmentation in different precast systems, and through the development of a simplified design procedure and software tools for practitioners to implement this design approach in precast buildings.

As Encast increases the trust and confidence of key stakeholders in this synergetic approach, it will lead to the integration of new knowledge and novel precast building design principles into common practice. This will be an innovation driver, with the potential to generate new products and services and to create new companies that contribute significantly to increasing building safety and societal resilience. In doing so, Encast is perfectly aligned with Sustainable Development Goals 8 and 11 and Target D of the Sendai Framework.

This work is supported by an ERC grant (Encast, 101188699) funded by the European Union. Views and opinions expressed are however those of the authors only and do not necessarily reflect those of the European Union or the European Research Council Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.